Troubleshooting and Fixing a Faulty Windshield Washer System - 2019 Ram 1500

Owning our Truck has been a dream so far, a few small issues that have been simple enough to handle. This winter presented another one of these small issues.

During a cold snap the washers stopped pumping the much needed blue juice onto the windshield leaving us with a dirty view. Living in Denver Colorado, a functioning windshield washer system is a must! Having it fail in the middle of a storm was the worst.

For a few weeks we carried a water bottle with us as an emergency wash waiting for the weather to warm up enough to look into the issue. Finally temps rose above 50°F and I was able to take a look.

Troubleshooting the Washer Fluid System

I was told the truck needed fluid and when I tested the switch in the cab I could hear the pump turn on, but no fluid came out of the nozzles. Oddly when I checked the fluid reservoir it was brimming full, something else must be going on…

The washer fluid system is simple:

- Reservoir holds the spare fluid

- A pump attached to the reservoir moves fluid when the switch is pushed

- Hoses connected through the engine compartment connect the pump to the nozzles

- Nozzles are attached to the hood to point at the windshield and spray the fluid out evenly.

Press the switch and spray should come out. Running the system with the hood up I noticed fluid leaking down from the engine side of the hood showing me that the pump works.

Somewhere under the hood liner was a break in the hose!

Removing the Hood Liner to Access the Hoses

To get to the hose I needed to remove the hood liner, the large fabric piece used to block sound and insulate the heat of th motor away from the hood. This liner is held in place with plastic retainer clips pressed into the steel hood structure.

Nothing I could do saved these little retainer clips. I gave up trying and just pried them off, with replacements on the way. The liner is not crucial however replacing any broken clips, and making sure the liner is securely in place so there is no way something could fall onto the motor is critical.

Try to not break the liner as it’s reusable. I placed a plastic pry bar under the pliers to pad the pry force from ripping through the liner.

Finding the Broken Hose

With the liner removed I found the culprit, the drivers side hose was no longer connected to the “T” at the first nozzle.

What I figure happened is the temperature dipped below the max the washer fluid could handle (high of 6°F, low of -24°F) and the driver tried to use the washers to clear an icy windshield. due to the blockage of frozen fluid in the nozzle, the connection gave under the hood.

Looking at the passenger side it seems someone else had this problem and attempted to fix it with some goop. This patch may have worked for a little but clearly there is a design bust here. The little rubber boots fail to maintain enough pressure around the hose to hold the full pressure produced by the pump when there is blockage on the line.

Instead of perpetuating this issue like the last guy did, I decided a full replacement was due.

Replacing the Hose for a Permanent Fix

Looking around the garage I was able to scrounge enough parts up to run a new hose from the engine compartment to the nozzle connections on the hood.

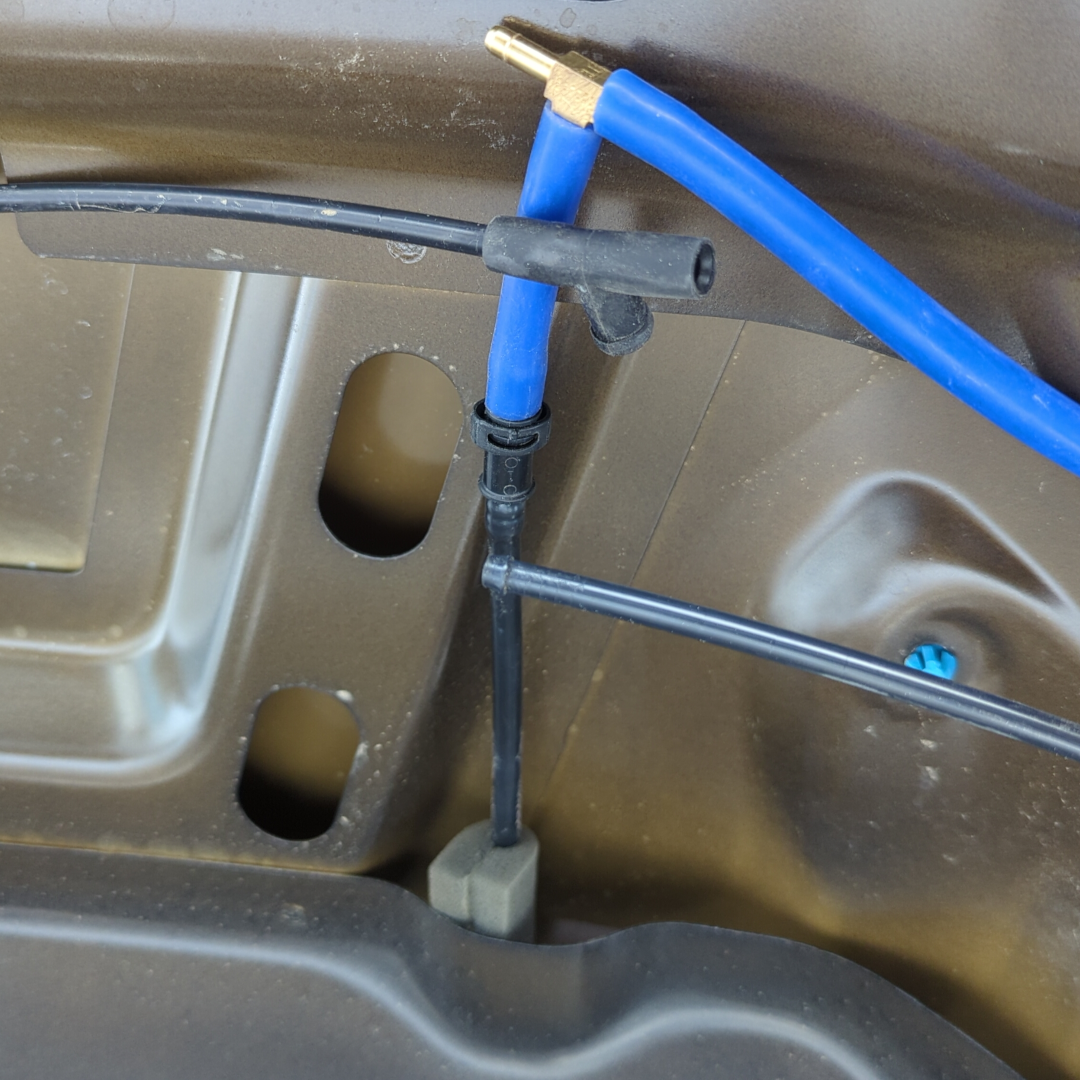

Brass “T’s” and some silicone hose was all that was needed for this repair.

Running the new hose in a similar path, making sure to avoid any pinch points with the hinge of the hood I replaces the old hard plastic hose and rubber fittings.

I zip tied the hose into place using the old hose tie downs and some clever routing through the hood structure.

The Final Product: A Fully Functional Washer System

I think the end result came out great, new hose routed in place of the old looks pretty good. Since this was a free-be with all found parts I can accept the color but if I had a choice I would have gone with black.

Once my replacement liner retainer clips come in the hose will hardly be visible.

Everything tested out fine when I tried the washer switch from inside the cab, fluid squirted out of both nozzles.

Now we can safely adventure back out in the next storm with confidence that our view will be clear, once I replace the washer fluid with something that can handle the cold a little better that is.